Jetting Micro Cable

There are three common methods to install underground fiber:

- Open trenching

- Pulling fiber in duct

- Jetting/blowing micro cable in duct

When jetting fiber, a stream of compressed air with a high rate of flow pushes the micro cable through a guide and innerduct. In addition to the compressed air which floats the micro cable, the cable is gently pushed through the duct by the jetting machine.

Jetted micro cable has four components:

- Micro duct

- Jetting apparatus

- Reduced-diameter micro cable

- Connecting/terminating hardware

The micro duct typically consists of multiple individual ducts, bundled into a single sheath. Each duct is connected by splices and connectors that route the micro cable from one continuous pipe to the next.

Pros and Cons of Jetting Micro Cable

Pros

- Saving duct space: micro cable is smaller in diameter

- Easy transport through bends and undulations along the fiber route

- Longer installation distances can be achieved

- Capstans, winches, pull tape are unnecessary when jetting micro cable

- Minimizes forces exerted on the cable by using compressed air to float the cable

- Special equipment is required on just one end of the duct route

- Greater safety for crews because less force is applied to materials

- Installation speed is increased

|

|

Cons

- Requires additional specialized equipment

- Micro cable requires micro duct to ensure its protection in the handhole/vault

- Micro cable requires a separate toning wire for location services, if required

|

|

For FTTH Applications

>>> Jameson NanoFlow

- Battery powered

- 0.8 - 3.6mm fiber cable OD

- 3,940 ft. blowing distance

- J101-160601800

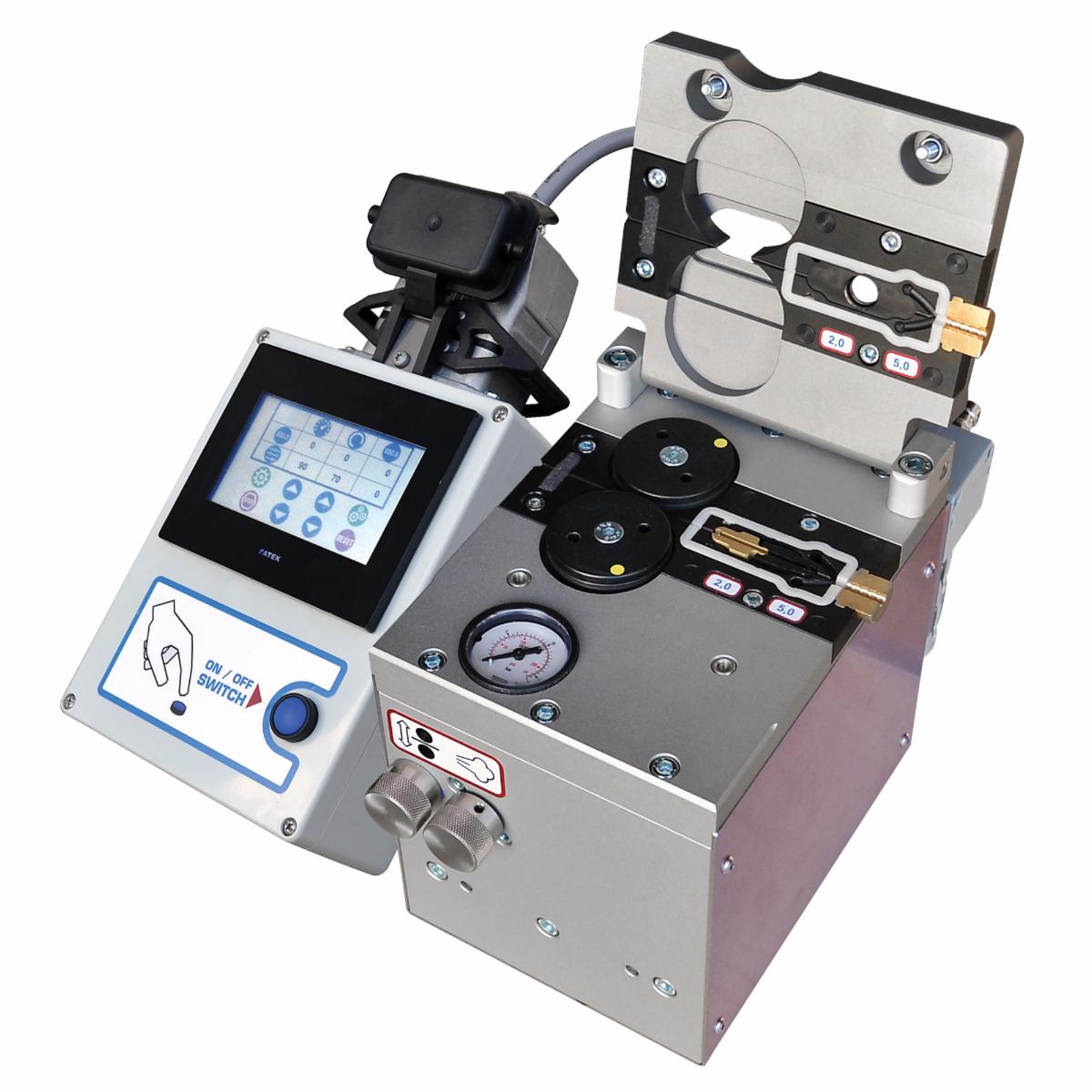

>>> Jameson MicroFlow

- 110/230 VAC

- 0.8 - 6.5mm fiber cable OD

- 8,200 ft. blowing distance

- J101-10051

For Access Network Applications

>>> Jameson MiniFlow Rapid

- Hydraulic

- 3 - 12mm fiber cable OD

- 11,485 ft. blowing distance

- J101-10031

For Backbone Applications

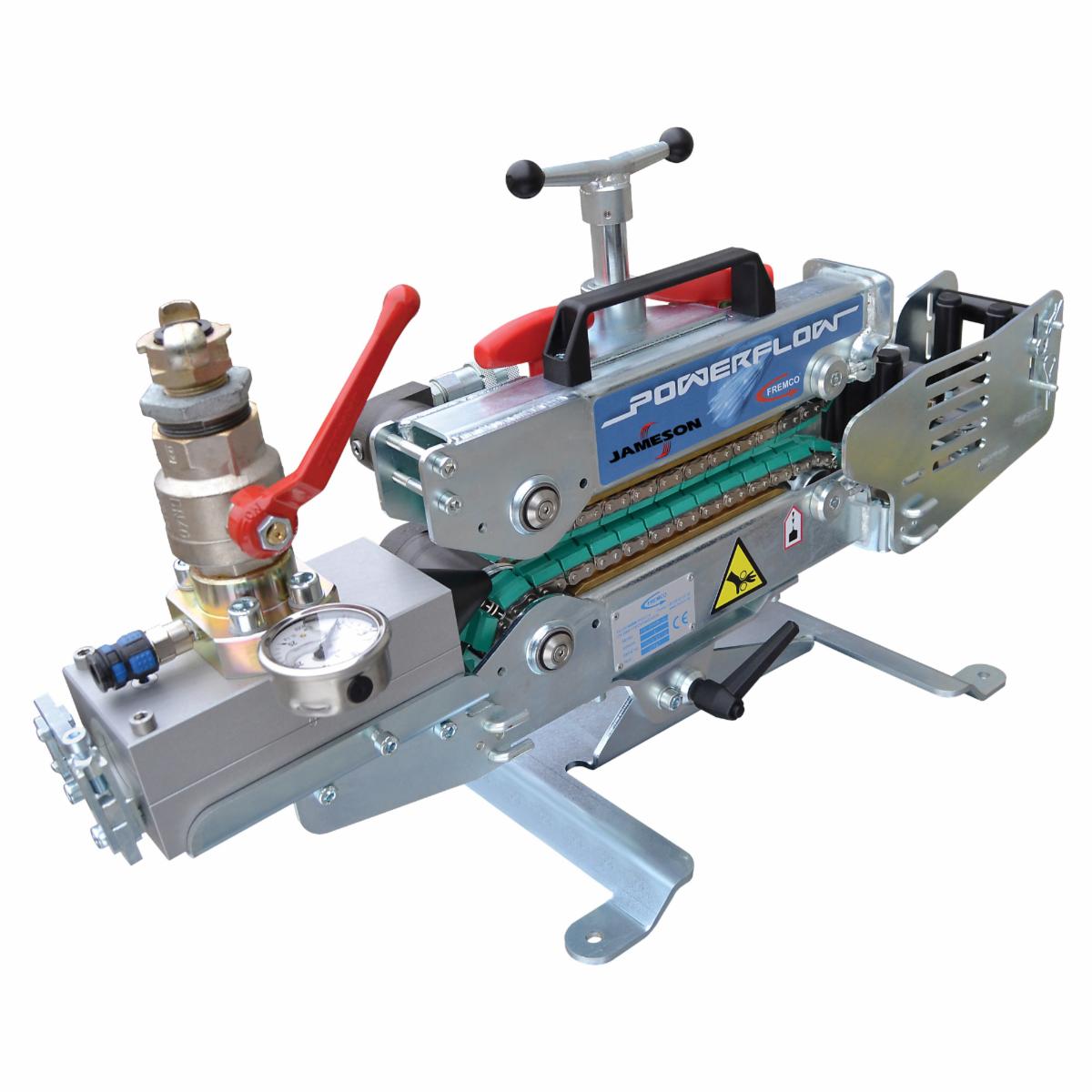

>>> Jameson PowerFlow

- Hydraulic

- 8 - 25mm fiber cable OD

- 32,810 ft. blowing distance

- J101-10001

>>> Jameson MultiFlow

- Hydraulic

- 8 - 32mm fiber cable OD

- 32,810 ft. blowing distance

- J101-10021

Compressor Aftercoolers for Fiber Blowing Machines

High-pressure air can achieve high temperatures that may cause melt damage to cables and ducts.

Aftercoolers are used between the compressor and the blowing machine to cool compressed air and remove water droplets before air enters the blowing machine.

>>> Aftercooler for MiniFlow

>>> Aftercooler for PowerFlow/MultiFlow